All-Axle Hub Motor

The Grin All-Axle Hub Motor

The Grin All-Axle hub is a direct-drive motor series we designed to be universally compatible with all the varieties of quick-release and thru-axle mounting standards that exist in the bike world these days. It solves the compatibility problem between hub motors and modern bicycle frames, it provides the benefits of direct drive without the traditional heft, and it simplifies installation with integrated torque arms and torque sensors.

Features

The All Axle motor has the following characteristics:

- 4.0 kg motor weight (vs >6kg for comparable generic DD motor)

- 0.35mm Laminations for low motor drag when pedaling unassisted

- Integrated Torque Arm with secure fork mounting clamp

- Fits Almost All Front Fork Standards (regular quick release, QR12x100, QR15x100, QR15x110 Boost, QR15x150 Fatbike, QR20x110

- Fits Most Rear Dropout Standards (135mm quick release, 12x142 Thru Axle, 12x148 Boost Thru Axle)

- Compatible with Single Side Installation on many trike and quad vehicles

- Uses 32 Spoke Holes for vastly more in stock rim options

- 18mm Disk Caliper Clearance fits most (but not all) calipers without spacers

- Statorade Compatible with side cover injection port

- Available in both metallic silver and black anodized finish

- Designed and Assembled in Canada

V3 Model Updates

In December 2023 we rolled out significant design update to both the front and rear All-Axle motor models. This is driven by two primary motivations:

1) To resolve the recurring issue of customers experiencing cable damage on front motors due to the small clearance to the spinning disk rotor.

2) To add both torque sensing functionality and SRAM-XD/XDR driver support to the rear motors.

Changes to the Front Design

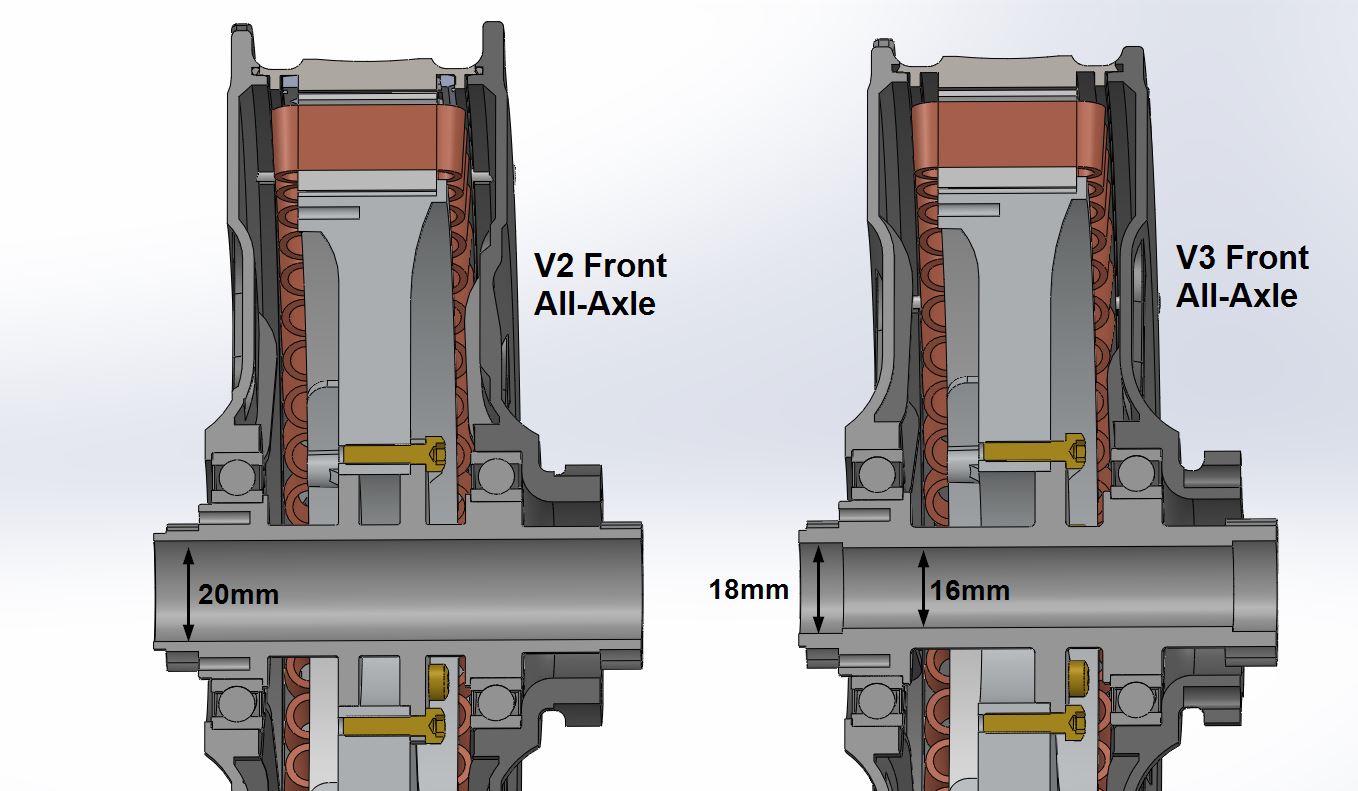

Axle: The front motor now uses an internal 16 mm bore rather than the 20mm bore of the original design. This gives us 2mm more room for the cable to clear the disk rotor. Unfortunately, it also means that the V3 front motor is no longer compatible with 20mm axles. The bicycle industry has long ago moved away from the original 20mm thru-axle fork standard to 12 and 15mm axles instead, so for most this is of almost no consequence. However, we will continue to make the V2 motors available for people who do require compatibility 20mm forks or single-side installations.

Adapters: All of the axle adapters for the V3 motors are different as they must fit into an 18mm recess and not a 20mm ID. We are clearly labeling each adapter set on our store as either a V2 or V3 model to reduce uncertainty, and will always carry a large stock of the V2 adapters to support customers over the years as they move their V2 motor from one bike to another.

Changes to the Rear Design

Freehub: The most significant change is the migration to a new freehub supplier that has options for integrated torque-sensing, rather than our original freehubs that only had basic magnet PAS encoder. There are three options now available

- Shimano HG Torque - This model uses the industry standard Shimano HG freehub body, but using the road rather than mountain standard. By default we are including a 1.5mm spacer to support the more common mountain cassettes, which should be removed if used with a Shimano road cassette.

- SRAM XDR Torque - The option for a SRAM XDR driver gives the ability to use high-end 11, 12, and 13 speed 1x cassettes that have super wide range and a small 10 tooth gear to simplify pedaling at high speeds. Both XD and XDR cassettes are compatible (XD with an included spacer)

- Shimano HG PAS - For those who don't need a torque sensor in their substance, we're planning in 2024 to also offer a less expensive version that has just a basic PAS sensor like our original rear hubs.

These sensors communicate with an internal circuitboard that generate a 0.8V signal at rest, which increases up to 4V as maximum torque is applied. The circuitboard also generates an equivalent 2 wire PAS output to support motor pedal cadence sensing and most importantly back-pedal regen

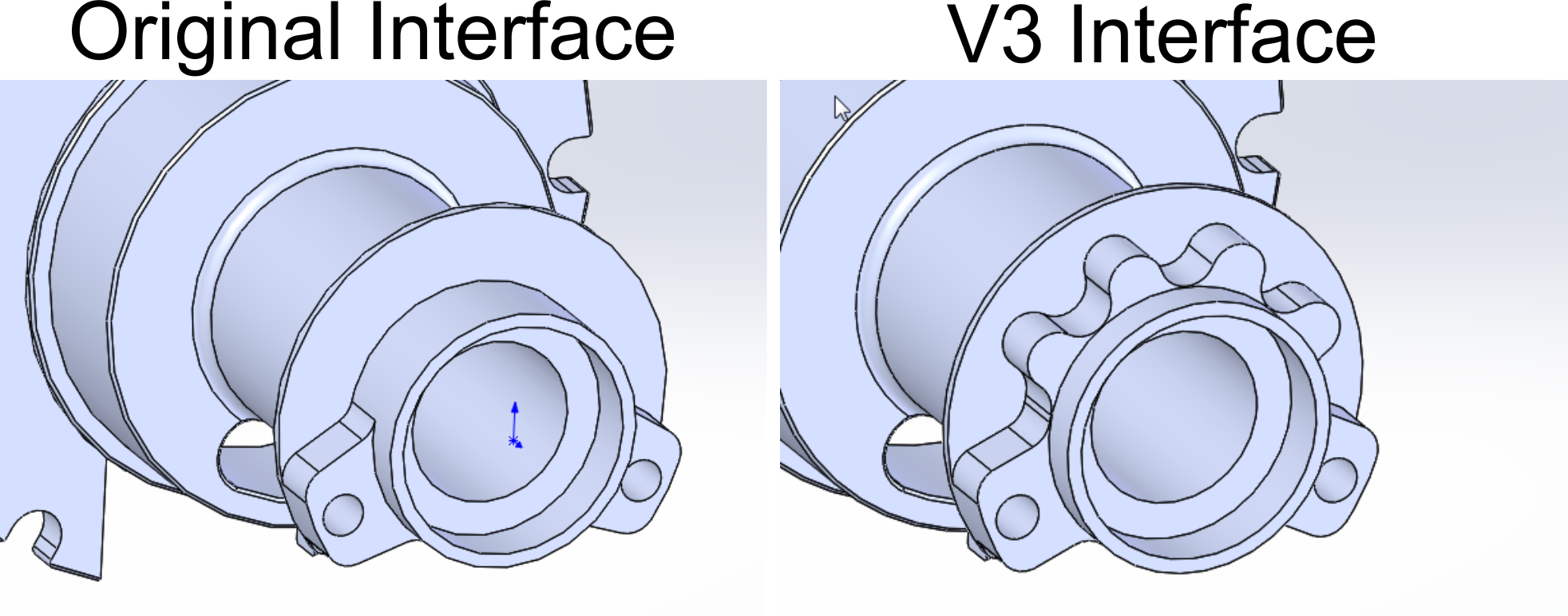

Torque Arm: The torque arm looks the same externally but internally it now features a set of internal splines in between the two screw holes, providing higher spinout resistance in anticipation of future higher motor models.

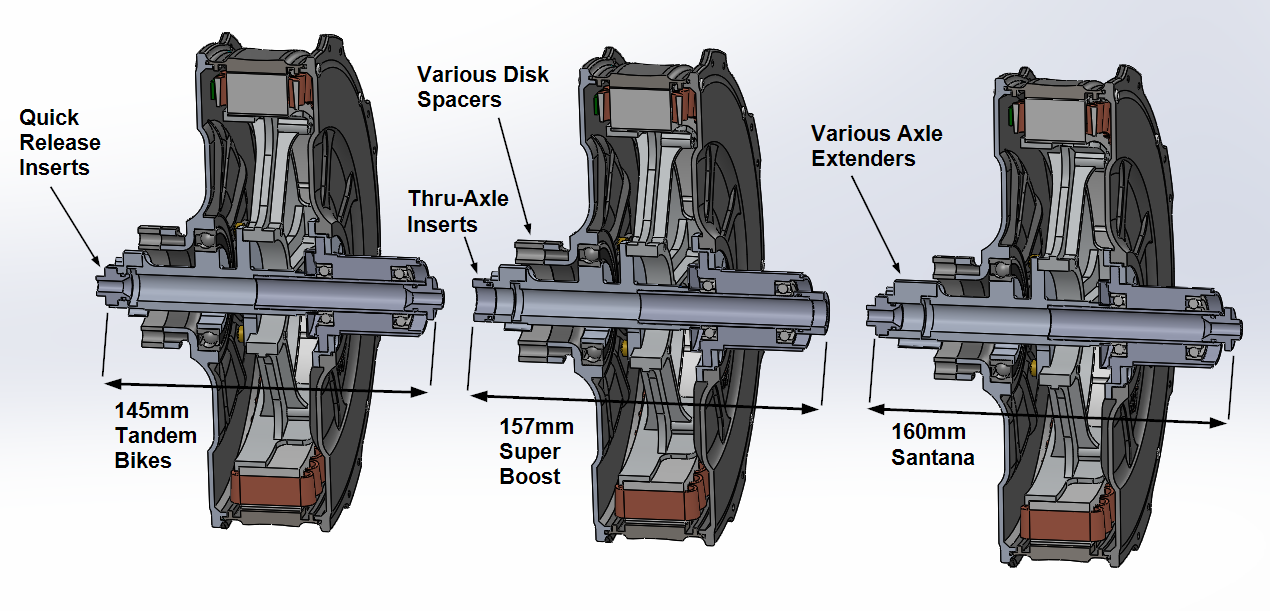

Motor Adapters: While the original rear motor had adapters for the three most common dropouts (135mm quick release, 142x12 thru-axle, and 148x12 boost thru axle), the V3 rear motors envision a much wider assortment of adapter sents, including -

- 145x9mm quick release for regular tandem bikes

- 157x12mm superboost thru-axle for mountain bikes

- 160x9mm quick release for Santana Tandem bikes

Disk Spacing:

Finally, the V3 rear all-axle motors are sized so that a 1mm disc spacer is required to correctly position the disc rotor in the bike frame. This increases the caliper clearance to the side plate from 18mm to 19mm which greatly increases the number of brake calipers that will fit without rubbing.

Changes to Both Front/Rear

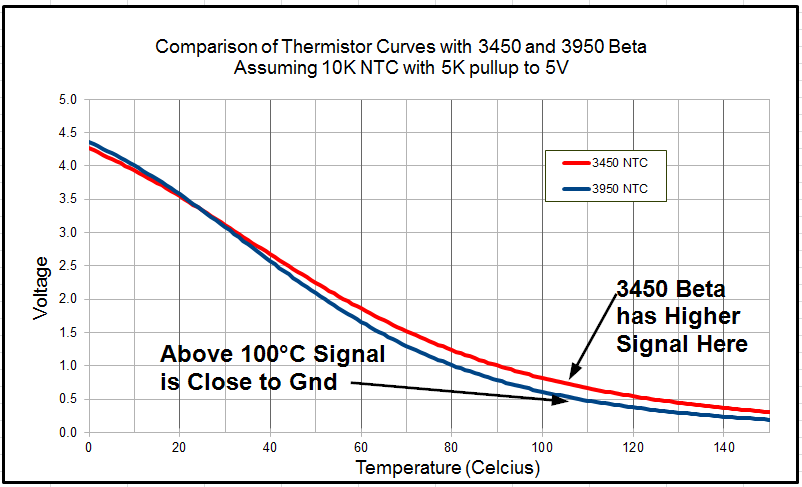

Thermistor Beta: The 10K NTC thermistor has been changed from one with a 3950 Beta constant to a 3450 Beta constant. This allows for better resolution and accuracy when measuring high motor temperatures, as there is a more discernable voltage change. Most hub motors from other manufacturers that have a thermistor include one with this Beta value, and it is already supported in our Cycle Analysts (V3.15 and later FW) and motor controllers.

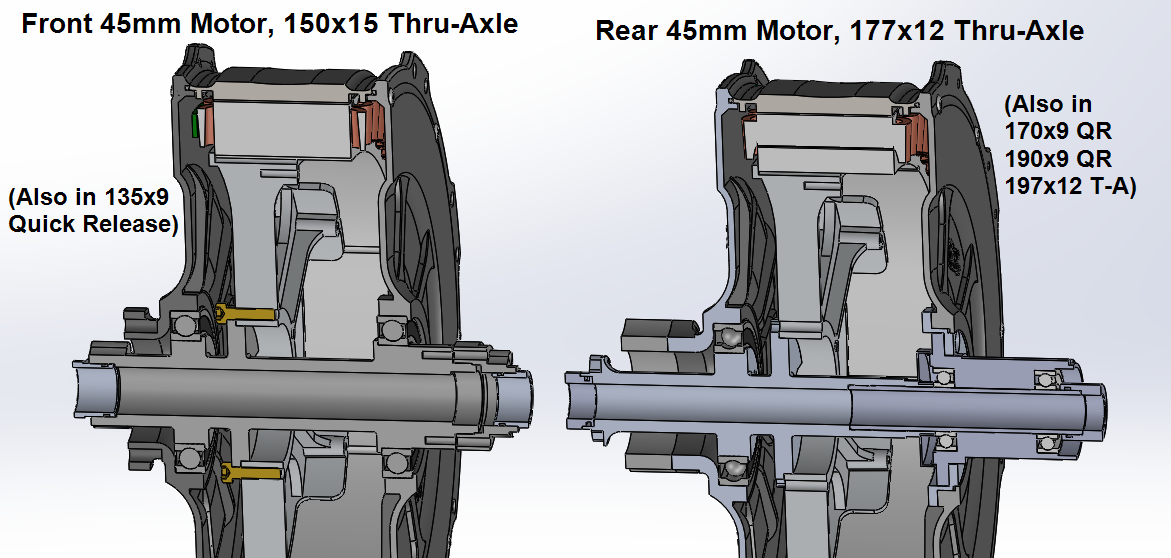

45mm Stator for Fabikes [expected Q2 2024]: A more powerful motor option using a 45mm stator instead of a 27mm stator is on the drawing board for better fatbike support. This increases the hub flange spacing making it easier to lace into fatbike rims, and it naturally increases the power and weight of the hub too. The front fatbike motor will work with 135x9mm quick release and 150x15 thru-axles, while the rear fatbike version will support 170/177 dropouts for 4" tires, and 190/197 dropouts for 5" tires.

Front Axle Adapters

The front motor requires axle adapters to fit inside the wide range of dropout standards. The V2 motor axle has a 20mm ID, while the V3 motor has a 16mm ID that expands to 18mm where the adapter fits in.

|

Standard Slotted Dropouts (100mm) |

These inserts allow the motor to fit in standard front forks with slotted dropouts using a regular quick release skewer to hold the motor in place. The vast majority of older bikes and new low to mid-range bikes will use this adapter |

|

12mm Thru-Axle (100mm) |

The 12 mm thru-axle is a relatively new standard for road bikes to gain the stiffness and security benefits of a thru-axle wheel at a lower weight than the 15 and 20mm sizes common in mountain bikes. These hubs have the standard 100mm dropout spacing. |

|

15mm Thru-Axle (100mm) |

The 15mm front thru-axle was introduced for cross-country and mountain bikes when the original 20mm thru-axle standard of downhill bikes was seen as overkill. The regular 15mm thru-axle uses the same 100mm hub spacing and disk rotor placement as regular quick release hubs |

|

15mm Boost Thru-Axle(110mm) |

These adapters are similar to the standard QR15 except that the right side insert protrudes an extra 10mm, making the overall hub 110mm wide instead of 100mm for wider flange spacing. |

|

Fatbike Slotted Dropout (135mm) |

This adapter set converts the front hub to have a 135mm axle length, commonly used on slotted dropout front fatbike forks. These forks can use either 10mm or 15mm rotor spacing, and we include an extra 5mm disk spacer to accommodate either. |

|

Fatbike 15mm Thru-Axle (150mm) |

This adapter set converts the axle to a 15x150mm thru-axle standard that is used on newer fatbike forks. A torque arm spacer effectively extends the axle by XXmm, and disk spacer brings the disk into similar alignment. Both 10mm and 15mm roor spacings are supported via an optional 5mm disk spacer. |

|

20mm Thru-Axle (110mm) |

This is the original thru-axle fork standard created for downhill mountain bikes and popularized in the early 2000's. It is still in common use on large travel suspension forks for serious off-road machines, but has been mostly replaced by QR15 size in regular mountain bikes. These Axle Adapters space both the left and right sides equally to build up the extra 10mm length. To fit the "20mm Boost" forks, a simple 5mm spacer is mounted under the disk rotor to position it closer to the fork. |

Rear Hub Adapters

The rear motors have a 12mm natural bore and uses end caps to fit the axle to either slotted dropouts or thru-axle frames.

|

135mm Slotted Dropout |

These end caps allow the motor to fit in a standard slotted rear dropout with a 135mm quick release skewer. The actual motor OLD is about 138mm. |

|

142mm Thru Axle |

With these end caps, the rear hub will fit in a thru axle frame with the original 142mm dropout spacing. Note that the actual V2 motor axle length is 145mm, while the V3 motor axle length is 143.5mm. This difference of a few mm wider than the nominal 142mm is mostly inconsequential. |

|

148mm Boost Thru Axle |

A slightly wider 'Boost' standard was created in the bike industry in order to provide greater stiffness and room for wider cassettes. The boost adapter has a longer length on the disc side end cap and a 4mm spacer under the disc rotor for proper alignment. |

|

145 Tandem Slotted Dropout |

This dropout standard is commonly used on tandem bicycles to support a wider flange spacing and a more symmetric lacing for a wheel that is less prone to buckling. Our adapter kit uses an 8mm axle extender and a 9mm disc spacer. |

|

157 Super-Boost Thru Axle |

This is another rear hub thru-axle standard that is slowly gaining ground with mountain bikes to have better chainlines with wide tires and 1x cassettes. The adapter kit uses a 13mm axle extender and a 13mm disk spacer. |

| 160mm Santana Tandem (V3 Only) |

This is a new tandem bike hub standard championed by Santana Tandems that uses slotted dropouts with a 160mm OLD. Both the freehub spacing on the right and the disk rotor spacing on the left are non-standard. It includes a 20mm axle extender a 9mm disc spacer plus the standard quick release end caps. |

| 167mm Santana Thru Axle (V3 Only) |

This is the thru-axle version of Santana Tandem's 160mm dropout but using thru-axle end caps. |

Motor Speed

The Grin All-Axle Motor is currently produced with three different windings; a slow 8 turn stator, a standard 6 turn stator, and a fast 5 turn stator. All three motor winds are capable of producing exactly the same torque and power outputs so the recommended motor model depends on your desired vehicle speed. The faster wind motors are more appropriate for small wheel diameters and/or lower battery voltages, while the slower motor winds are more common with larger wheel sizes and higher battery voltages.

The following table shows the unloaded speed of each motor winding at common battery voltages in 20" 26", and 29" (700c) wheel sizes.

| Slow 8T Wind (7.5 rpm/V) | Standard 6T Wind (10 rpm/V) | Fast 5T Wind (12 rpm/V) | |||||||

| 20” Wheel | 26” Wheel | 29” Wheel | 20” Wheel | 26” Wheel | 29” Wheel | 20” Wheel | 26” Wheel | 29” Wheel | |

| 36V Battery | 26 kph | 34 kph | 37 kph | 34 kph | 45 kph | 50 kph | 41 kph | 54 kph | 60 kph |

| 48V Battery | 34 kph | 45 kph | 50 kph | 46 kph | 60 kph | 67 kph | 55 kph | 72 kph | 80 kph |

| 52V Battery | 37 kph | 49 kph | 54 kph | 50 kph | 65 kph | 72 kph | 60 kph | 78 kph | 87 kph |

| 72V Battery | 52 kph | 67 kph | 75 kph | 69 kph | 90 kph | 100 kph | 83 kph | 108 kph | 120 kph |

The top speed under any kind of load is going to be less than this value, and we recommend using our motor simulator for exact performance details of any given combination of motor, battery voltage, and controller model.

Motor Power

The Grin motor uses a 27mm wide 205mm diameter stator and has similar continuous power and torque capabilities as other direct drive hub motors of this size. However being optimally designed for weight reduction it has less metal mass to absorb heat. Under heavy loads the core temperature will rise at a faster rate than you would see on an otherwise identical but heavier hub, and for those reasons we recommend Statorade in the motor when used in more demanding applications.

The table below shows both the continuous and 5 -minute power capability of the motor at various RPMs with and without Statorde motor coolant. Notice again that the motor winding speed does not impact the power capability of the motor, this table holds true for all three winding options.

| Wheel Speed | Without Statorade | With Statorade | |||

| Continuous | 5 Minute | Continuous | 5 Minute | ||

| 100 RPM | 250 W | 500 W | 340 W | 575 W | |

| 200 RPM | 560 W | 1040 W | 785 W | 1235 W | |

| 300 RPM | 900 W | 1590 W | 1275 W | 1830 W | |

| 400 RPM | 1250 W | 2110 W | 1840 W | 2420 W | |

For a more detailed understanding we recommend using our motor simulator or trip simulator applications to properly predict the capability of this motor in any specific usage scenario.

Single Side Applications

A unique feature of the front All-Axle hub design is its ability to work in applications requiring a single side mount. This allows the side wheels of trikes and quads to be readily electrified for the first time, and is especially popular with tadpole trikes running an internal gear hub rear wheel.

A unique feature of the front All-Axle hub design is its ability to work in applications requiring a single side mount. This allows the side wheels of trikes and quads to be readily electrified for the first time, and is especially popular with tadpole trikes running an internal gear hub rear wheel.

Unlike front bicycle forks where there are industry standards (admittedly a lot of standards, but standards at least), the wheel mounting strategy on trikes is all over the map, and unique adapters are required for most vehicle models. We've taken the approach of using the disk caliper mount as an anchor point to hold the wheel and lock the axle against rotation.

|

|

The popular catrikes are ideal for the V2 Grin Hub motor because they already use a 20mm spindle, and they adopt the rear ISO2000 disk caliper mounting standard for both the left and right wheels. |

|

|

The terratrike rovers also have a 20mm spindle, but they use a front ISO disk mount and the shaft has a shoulder that prevents the hub from sliding on as far as would be ideal. We accommodate the terratrike axles with a two-piece torque arm that provides the necessary spacing for where the motor fits in place. |

|

|

This adapter bolts onto a custom machined All Axle Hub Motor to allow for single side mounting to the spindle of certain Icetrike tricycles. The two-piece adapter secures the motor axle to the trike frame via the disk caliper mounting holes. This adapter requires a shim insert to step down the ID of the motor axle to 12mm. |

|

|

The Greenspeed trikes use a smaller 12mm diameter spindle and have a disk caliper location with Rear IS2000 caliper placement. We have a similar 2 piece arm that can be flipped 180 degrees for working on either side. This also requires a shim to step the axle ID down to 12mm. |

HP Velotechnik |

The popular german brand HP Velotechnik makes trikes that all use a 12mm spindle but use a post mount rather than an ISO disc mount. To fit the All-Axle motors on these trikes, we have a disc caliper mounting block that repositions the brake outwards to align with the motor and increases the radial offset for a larger 180mm rotor. The torque arm in this setup is secured to the two fender bolts via a stainless steel plate rather than to the caliper mount. The hardware for the left and right side models are similar, differing only in the direction of bend on the stainless torque arm plate. |

|

|

The splined arm is available by itself for doing DIY mounts on other vehicle types. The two bolt holes allow you to interface with a separate flat plate of metal that can attach under the disk caliper or other frame location on the frame to lock the axle from spinning. |

One Side or Both?

A trike with dual Grin hub motors can be insanely powerful and will be able to rocket up the steepest hills with amazing efficiency, but it is also quite expensive to do a full conversion with two specialized motors and motor controllers. You can also run a tadpole or delta trike with just a single side wheel motor and leave your original wheel on the other side. In general this does not result in any lopsided steering or handling issues and allows for a ligher weight and more economical conversion.

A trike with dual Grin hub motors can be insanely powerful and will be able to rocket up the steepest hills with amazing efficiency, but it is also quite expensive to do a full conversion with two specialized motors and motor controllers. You can also run a tadpole or delta trike with just a single side wheel motor and leave your original wheel on the other side. In general this does not result in any lopsided steering or handling issues and allows for a ligher weight and more economical conversion.

Wheel Lacing

Unlike most hub motors, the All-Axle uses 32 spoke holes rather than 36 spoke holes in order to fit the much larger availability of 32 hole rims. The spoke holes are paired sufficiently close that there is NO NEED to have the spokes cross over. With a radial lacing the spokes have an effective angle that is the same as a regular hub with a triple cross. That said, you are free to do a single cross lacing if you prefer the look.

One not-so-obvious detail is that the spoke flange of the All-axle motor is designed for the spokes to be laced with the elbows in and the head facing outwards. The flange has a couterbore for the spoke head on the outside, and is wide enough apart (49mm, vs 25mm for typical motors) that there is sufficient triangulation with all spokes elbows in. If the wheel is laced with the spoke elbow facing outwards, it results in a bending force on the flange that pushes the entire center of the side plate outwards by 1-2mm. This can result in the motor axle developing play to slide left and right.

Difference between Versions

The original V1 All Axle hub motor was in limited production from 2013 until early 2019 and used a large 45mm ID thin section bearing on the side covers. This allowed for a generous amount of room for the heavy gauge phase wires to pass through the axle, but the thin section ball bearings could have short lifespans in setups with frequent exposure to the elements.

In the spring of 2019 we released an updated V2 Grin motor design based on feedback and experience. This updated model has the motor cable exiting on the disk side of the motor rather than the non-disk side to facilitate single side installations, and it uses a wider 35mm ID ball bearing standard with a custom tooled lip seal to prevent ingress and egress. These changes increased the overall motor weight a small amount, but the improved robustness and versatility was worth it.

| Property | V1 | V2 | V3 |

| Main Bearing | 45x58x7 (6809) | 35x55x10 (6907) | Same as V2 |

| Bearing Seal | Standard Dust Seal | Double Lip Seal | Same as V2 |

| Cable Exit | Non-Disk Side | Disk Side | Same as V2 |

| Axle ID | 20mm | 20mm | 16mm |

| Torque Arm | Non-Disk Side | Non-Disk Side | Same as V2 |

| Connector | Anderson +JST SM | HiGo L1019 | Same as V2 |

| Side Plate Seal | Sillicone Sealant | O-Rings | Same as V2 |

| Statorade Compatibility | So-so (can leak through bearings) | Excellent | Same as V2 |

| Weight | 3.95 kg | 4.05 kg | 4.1 kg |

| Magnets | N35UH | N40SH | Same as V2 |

| Thermistor | 10K NTC, Beta 3950 | 10K NTC, Beta 3950 | 10K NTC, Beta 3450 |

| Property | V2 | V3 |

| Freehub Style | Shimano HG Mountain | Shimano HG Road, or SRAM XD |

| PAS Poles | 12 Pulses / Revolution | 9 Pulses / Revolution |

| Torque Sensing | None | Yes, 28.3 Nm/V |

| Thermsitor | 10K NTC, Beta 3950 | 10K NTC, Beta 3450 |

| Available Adapter Sets | Quick Release: 135x9 Thru-Axle: 142x12, 148x12 |

Quick Release: 135x9, 145x9, 160x9 Thru-Axle: 142x12, 148x12, 157x12, 167x12 |

| Torque Arm | 2 Lobes Only | 2 Lobes plus 4 splines |

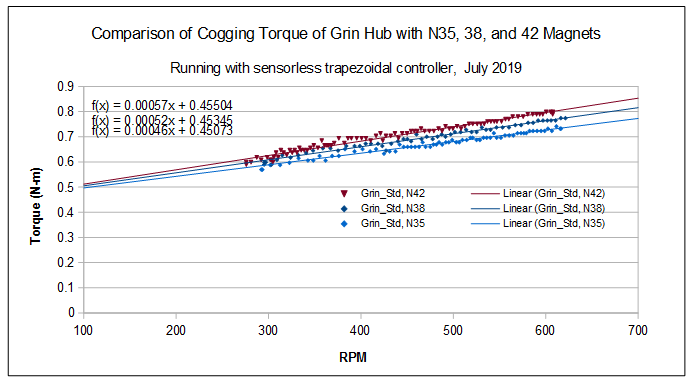

In addition to the mechanical changes we also updated from N35 to N40 grade magnets. Stronger magnets allow the motor to produce more torque for hill climbing with less heat loss, but they also increase the drag of the motor when riding without power. In our original design we erred on having lower rolling drag because at the time we felt this was more important than efficiency on hill climbs, but the Virtual Electronic Freewheeling feature in the Phaserunner/Baserunner controllers has shifted the balance and we switched to a higher strength magnet.

As a result the V2 and V3 motors spin about 5% slower than the V1 models. They have about 10% more drag torque but they can also climb hills with 10% less heat generation.

Technical Specifications

| Slow (8T) | Standard (6T) | Fast (5T) | |

| kV | 7.5 rpm/V | 10.0 rpm/V | 12.0 rpm/V |

| Phase to Phase Resistance | 268 mΩ | 145 mΩ | 100 mΩ |

| Phase to Phase Inductance | 680 uH | 380 uH | 260 uH |

| Hysteresis Drag Torque | 0.45 Nm | ||

| Eddie Current Drag Torque | 0.0005 Nm/rpm | ||

| Spoke Flange Diameter | 214 mm | ||

| Flange Spacing | 49 mm | ||

| Magnetic Pole Pairs | 23 | ||

| Motor Weight | 4.05 kg (8.9 lb) Front / 4.30 kg (9.4 lb) Rear | ||

User Manuals

3D CAD Models

We have made available full 3D models and drawings of the front and rear motors with various adapter sets in order to facilitate vehicle integration.

Videos

Background

The All-Axle motor has been a long development project for Grin to produce a direct drive hub motor that was lightweight and compatible with all Thru Axle and quick release fork standards. The idea first took roots in 2010 when we were impressed with the performance of large diameter direct drive hub motors being imported from china, but increasingly frustrated with the poor mechanical tolerances and bike fitment. While prototyping these mechanical improvements we also saw considerable opportunity to reduce the mass of the hub without affecting the torque output.

These earlier videos filmed from Ken (owner of a Calgary based ebike store) as he was passing through town in 2010 show the early development and thought process:

Since then we've gone through a number of design revisions, enhancements, mold toolings, and several pilot production batches while working out many kinks along the way. The hub was really put to the test in several touring trips (such as 2013 cargo biking Vancouver to San Francisco, and the 2018 Sun Trip solar bike race) and has finally come of age in 2019 with the V2 model when we switched to a wider and more rugged bearing, cable exit on the disk side, and a move to o-ring seals rather than silicone sealant for the side plates and screws for more consistent mass production and easier servicing.

Marine Motor - PAUSED

UPDATE: The Marine Motor development was paused in 2022 as Grin needed to focus on updates to our core ebike kit offerings and manufacturing capabilities. We hope to resume this project in full capacity in 2024 and will email everone who has expressed interest once we re-embark on this project.

We are actively developing a Marine version of our All Axle motor for people interested in electric sailboats conversions. The ~4kg motor can directly replace a much more massive diesel engine, and it is perfectly matched to drive the shaft 1:1 with no transmission required. Our standard width Grin motor with a 27mm wide stator can effectively replace an 8 horsepower engine, while a fatter 45mm stator option could replace a 12 hp diesel. This should broadly cover most sailboats with the 24-32 foot realm, or larger vessels if you don't mind being under powered.

We are planning to do a pilot launch of this motor in summer 2021 and are currently looking for potential pilot customers in BC lower mainland or Vancouver Island. Ideally these are people who have an existing sailboat with an inboard engine that is due for replacement, and with the drive shaft still in place. If that situation rings a bell and you have a strong interest in going electric, please fill out the google form below:

Where to Order

The Grin All Axle hub motors are available in stock at our shop in Vancouver and also sold through dealers all over the world, including ebike-solutions in Germany, Declic-Eco in France, BikeToTheFuture in Switzerland, and BikeSwift in the USA

Canadian

Canadian

Catrike

Catrike Terratrike

Terratrike Icetrike

Icetrike Greenspeed

Greenspeed DIY

DIY Full All-Axle Conversion Kits from our Online Store

Full All-Axle Conversion Kits from our Online Store