G310-G311

There are countless manufacturers and models of geared hub motors for ebikes, normally categorized as 250W or 350W machines. These small geared motor are often ideal for ebike conversions where the rider does not require large amounts of assist. They are lightweight, discrete due to their small diameter, and generally both inexpensive and well built. Our Project Gallery has quite a few examples of conversions done by our customers using these motors.

We've stocked a variety of motors of this class in the past (Tongxin, Outrider, G01) but now have settled on these as our preferred mini motor choice for the following reasons:

Key Features

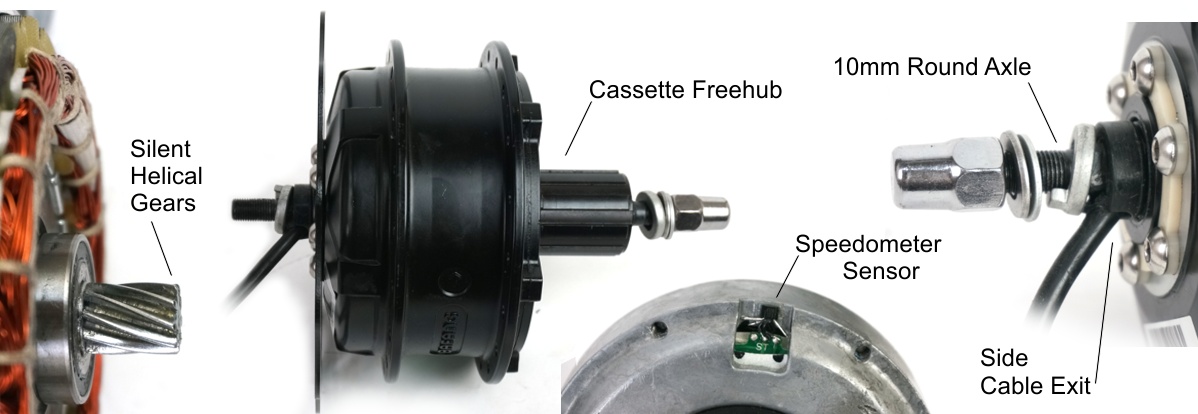

- Totally silent drive: We've grown accustomed to geared motors emitting a buzz while running. It's not that loud, but it does detract from the blissful peace you can expect while riding a bicycle in quiet neighborhoods. Well the G310/311 motors are completely smooth and silent over their entire speed range due to helical gears in the first reduction stage. If you've been put off geared motors because of the noise, these little hubs will change your perspective. They are smooth as silk.

- Side Cable Exit: These motors have an axle cut for side exit of the motor cable rather than running through the end. This facilitates changing axle hardware (nuts and washers) since they don't need to pass over connectors, and it makes the cable less likely to suffer damage as they exit from inside the bicycle dropout.

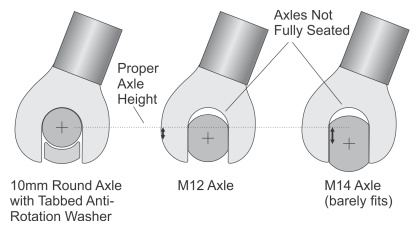

- Round axle: Most ebike hub motors have larger 12mm/14m axles that are ground flat on the sides, but this results in the axle of the motor sitting further down in the dropout than a normal bicycle hub causing the disk rotor to not fit all the way in the caliper, and it often requires filing the dropouts to get the motor in. The G311 and G310 hubs have a 10mm round axle to avoid that, with integral anti-rotation washers to transmit spinout torque further down the dropout slot.

- Easy Disassembly: Many models of geared motor are assembled with two halves that thread together or joined with an interference fit, and are nearly impossible to open up without special tools. Bafang has done an excellent job in making motors that are bolted together and can easily come apart for service and repair. (See our disassembly video)

- Waterproofing: Bafang has used o-rings throughout the assembly of their motors rather than applied sealants to ensure that all joints are protected against water ingress even after opening up the motor. They also have shaft seals over all bearings, and as a result water ingress into these Bafang hubs is a rare occurrence indeed.

- Internal Speedometer Sensor: The motors have a 6 pole speedometer built into the motor shell, allowing the use of a Direct Plug Cycle Analyst (CA3-DP or CA3-WP) for speed readings rather than requiring a -DPS device with separate spoke magnet and speed sensor.

- Cassette Freehub compatibility: The G310 motor uses a Shimano compatible cassette freehub body instead of a threaded freewheel, making it compatible with modern bicycle drivetrains, including the 9 and 10 speed systems that are fast becoming the norm. It will also fit 11 speed standard Shimano mountain bike cassettes, but not 11speed Shimano road cassettes, as they require a longer freehub body.

2021 Product Update

After some long drawn-out efforts with Bafang we've managed to have two significant updates made to our current supply of G310/G311 motors.

- Combined Speed/Thermistor: All the G31x motors at Grin now have a dual speed/temperature signal on the extra white wire, rather than just a simple speed sensor. Our Baserunner_Z9 motor controllers decouple this signal so that you can now see motor temperature on the Cycle Analyst display and use thermal rollback to prevent the motors from overheating even when used well beyond their nominal power. The thermistor used in these motors is wired a bit differently than our standard motor thermistor. So to see accurate temperature readings it is essential to use the V3.15 CA firmware. For the temperature sensor type, select "NTC Bafang" from the menu. The standard "10K NTC" thermistor option in the 3.14 and earlier firmware will under-report the motor temperature.

- Stronger Magnet Adhesive: The fast wind 8T motors had their rotor magnets glued on with a stronger and higher temperature rated adhesive to eliminate the risk of magnets coming loose at high RPM's. We tested this adhesive up to 800rpm and at over 100oC without any failures, while the stock adhesives would normally see magnets coming loose at around 400 rpm.

Power Levels, Speed, and Winding Options

The nominal power rating of 250W from Bafang doesn't mean a whole lot. These motors can put out 20 Nm of torque continuously and upwards of 40 Nm for short times without overheating. At higher speeds (like 40 kph) this translates into a solid 600-700 watt continuous power levels, while the corresponding power at lower speeds is more like 200-300 watts. Usage beyond 50 Nm is not recommended as there is high risk of stripping the gears.

We stock the motors in 3 different winding options, a very fast (7T, 11.9 rpm/V) ideal for 16" rims, a fast wind (8T, 10.5 rpm/V) intended for 20" wheels, and a standard wind (10T, 8.5 rpm/V) that is appropriate for 26"/700c builds. With this combination of winding choice and wheel diameter, you will achieve cruising speeds of 30-35 kph with 36V battery packs and 40-45 kph with 48V/52V packs. The image below shows the performance chart for each of the 3 windings with both 36V and 52V battery packs.

For exact performance details with any combination of wheel size, battery voltage, and motor winding please have a look at our motor simulator page (Standard Wind, Fast wind, VeryFast wind). We have these hubs thermally modeled as well so you can see if your application needs will be pushing them to overheating. In cases where the motor will be prone to overheat with your setup, then we would recommend a larger and more poweful geared motor like the eZee hub.

Internal Construction

The G310/311 motors have an unusual construction. Most geared hub motors have an outrunner motor spinning the sun gear of a single stage planetary gear reduction to the shell. The G31X motors instead have a small inrunner motor turning a helical cut sun gear. It does not have a common axle that runs through the entire motor. This allows for a smaller diameter sun gear than a typical configuration. That small gear diameter combined with the double stage on the planet gears produces an impressive 11:1 total reduction ratio allowing the smaller / lighter motor to still produce a decent torque at the wheel.

The helical first stage gears allow for a smooth transmission with almost no vibration or noise. But this spiral cut also produces a small axial force component that must be countered with thrust bearings. These needle thrust bearings are visible under the planet gears, and care should be taken not to loose them during any motor disassembly.

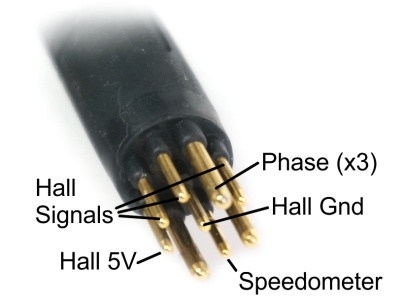

Wiring Pinout

These motors are terminated with a waterproof HiGo Z910 overmolded connector which has the convenience of phase and signal wires in a single plug. However, it does not allow for the user to play around with hall and phase pinouts which is often required when pairing with a 3rd party motor controller. Fortunately most controller and motor vendors using this connector have chosen a compatible pin configuration. The 6th signal wire is used for the speedometer, which pulses 6 times per wheel revolution. On the matching 20A Grinfineon controllers, this speed signal is routed back to the CA-DP plug for the Cycle Analyst to have a speed readout.

These motors are terminated with a waterproof HiGo Z910 overmolded connector which has the convenience of phase and signal wires in a single plug. However, it does not allow for the user to play around with hall and phase pinouts which is often required when pairing with a 3rd party motor controller. Fortunately most controller and motor vendors using this connector have chosen a compatible pin configuration. The 6th signal wire is used for the speedometer, which pulses 6 times per wheel revolution. On the matching 20A Grinfineon controllers, this speed signal is routed back to the CA-DP plug for the Cycle Analyst to have a speed readout.

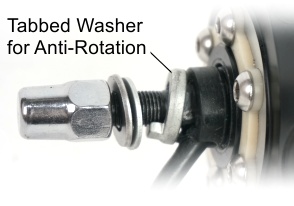

Washer Stack and Torque Arm

These motors do not have intrinsic flats on the axle for preventing axle spinout. They have a keyed washer that fits inside the forks and has a tab that engages with the bottom of the dropout slot. This gives the same kind of leverage against spinout as you'd have from a large 14mm flattened axle, with the benefit that the motor axle center is in the same location as a normal bike hub, and without the oversized M14 nuts and washers that don't fit inside the lawyer lips. On the downside there is no facility for external torque arms to move the reaction torque further up the fork blade, all the torque is resisted at the dropout slot via these washers.

These motors do not have intrinsic flats on the axle for preventing axle spinout. They have a keyed washer that fits inside the forks and has a tab that engages with the bottom of the dropout slot. This gives the same kind of leverage against spinout as you'd have from a large 14mm flattened axle, with the benefit that the motor axle center is in the same location as a normal bike hub, and without the oversized M14 nuts and washers that don't fit inside the lawyer lips. On the downside there is no facility for external torque arms to move the reaction torque further up the fork blade, all the torque is resisted at the dropout slot via these washers.

Most bicycle dropouts have more than adequate strength to resist spinout from the washer tabs. However, if you have a front fork with aluminum dropouts, there is not much margin between the motor torque and dropout failure. For installation on bikes with alloy dropouts, we have a specially made inside torque arm that replaces the left side anti-rotation washer and has an arm that bolts to a fender eyelet. In addition to a regular washer, lock washer, and barrel nut, there is also a thin 1mm spacer washer that is available in the washer stack. This can be placed under the tabbed anti-rotation washer to give a bit more clearance between the side of the motor and the fork, which can sometimes be handy for disk rotor alignment, fitting 9 or 10 speed freehubs, or giving a bit more room for the wide part of the fork blade to not rub against the side of the motor.

Most bicycle dropouts have more than adequate strength to resist spinout from the washer tabs. However, if you have a front fork with aluminum dropouts, there is not much margin between the motor torque and dropout failure. For installation on bikes with alloy dropouts, we have a specially made inside torque arm that replaces the left side anti-rotation washer and has an arm that bolts to a fender eyelet. In addition to a regular washer, lock washer, and barrel nut, there is also a thin 1mm spacer washer that is available in the washer stack. This can be placed under the tabbed anti-rotation washer to give a bit more clearance between the side of the motor and the fork, which can sometimes be handy for disk rotor alignment, fitting 9 or 10 speed freehubs, or giving a bit more room for the wide part of the fork blade to not rub against the side of the motor.

Disk Brake Compatibility

Both the G310 and G311 motors have the mounting holes for a 6-bolt ISO disk rotor. If you aren't using a disk, then be sure to leave the plastic spacer and M5 bolts in place to prevent water ingress into the disk mounting holes. Ideally the disk rotor mount will be 10mm from the axle end on a front motor and 15mm on the rear. The G311/G310 motors are slighly less than this. Most disk calipers have sufficient left/right play in their mounting to accommodate that, but if not then the 1mm spacer washer can be placed on the axle to give a bit more room.

Both the G310 and G311 motors have the mounting holes for a 6-bolt ISO disk rotor. If you aren't using a disk, then be sure to leave the plastic spacer and M5 bolts in place to prevent water ingress into the disk mounting holes. Ideally the disk rotor mount will be 10mm from the axle end on a front motor and 15mm on the rear. The G311/G310 motors are slighly less than this. Most disk calipers have sufficient left/right play in their mounting to accommodate that, but if not then the 1mm spacer washer can be placed on the axle to give a bit more room.

Controller Options and eRPM

The G310 motor have a large 11:1 gear reduction and 16 magnet rotor producing 88 effective pole pairs, which is higher than the 40-50 effective poles in most other geared motors. In many situations this puts the electrical commutation frequency (eRPM) at cruising speeds that is outside the range of sensorless controllers. The table below shows the eRPM of the G310 motors at different speed and wheel size combinations so you can see if your particular controller will have an issue or not in sensorless mode. The motors have the Higo Z910 conncector on them and we supply a plug-in compatible 20A Grinfineon controller with the kits which is connected in sensored mode for no eRPM limit.

Bicycle Fitment

The combination of cassette freehub, 138mm and 100mm axle lengths, 10mm round axles, and ISO disk rotor compatibility makes these motors a great fit for modern bike conversions. However there are a few things to watch out for.

- Dropout Filing: Even through these motor axles are smaller than normal hub motors, it's still the case that some dropout slots will still be slightly too narrow for the axle to slide in. If that's the case, you will need to file the dropout slot wider until the 10mm round axle can drop into place.

- Axle OLD: The rear G310 motor has a 138mm rather than 135mm axle OLD. Spreading a 135mm standard bike dropout to 138mm is generally no problem, that's just just 1.5mm on either side and can stretch by hand with minimal force.

- Cassette Stack Height: Depending on the bicycle frame, with a 9 or 10/11 speed cassette an additional 12mm washer is sometimes needed on the right side to accommodate the larger gear stack and have the chain clear the dropout. This will increase the OLD to 139mm.

- Fork Rubbing: The G311 front motor is narrower than most of the other front geared motor models and is less likely to interfere with wide fork blades than say the G01 model. Below is a 1:1 scale side view drawing that can be printed and cut out to check the fit if you are concerned about fork clearance. If the interference is on the order of 1mm or so then the addition of an inside washer will space the fork out sufficiently far to clear.

Link to G311 Motor 1:1 Scale Side View.

Limitations

There are two limitations that should be understood when using this hub motor outside of the ~25 kph european ebike application that Bafang had intended for them, related to the gear strength and the maximum motor RPM where the outrunner magnets are at risk of flying off.

Stripping Gears

As discussed earlier, the helical cut gears in the G310/G311 motors are wonderfully smooth and silent but they are not designed for excessive torque levels. These gears can strip in setups that allow too much phase current and torque through the motor. Bafang rates the motors for 30 Nm, and for reliability sake we recommend limiting the peak motor torque to about 40 Nm, either with a phase current limit (ideal, allows for higher power at higher speeds) or with a limit to the maximum battery current so that input power off the line is capped at about 500 watts. Our 20A Grinfineon controller already has a 40A maximum phase current programmed in that works well, while the Phaserunner or Baserunner allow you to customize this setting exactly. Up to 40 amps can be used on the standard winding, 48 amps on the fast winding, and 55 amps for the very fast winding.

As discussed earlier, the helical cut gears in the G310/G311 motors are wonderfully smooth and silent but they are not designed for excessive torque levels. These gears can strip in setups that allow too much phase current and torque through the motor. Bafang rates the motors for 30 Nm, and for reliability sake we recommend limiting the peak motor torque to about 40 Nm, either with a phase current limit (ideal, allows for higher power at higher speeds) or with a limit to the maximum battery current so that input power off the line is capped at about 500 watts. Our 20A Grinfineon controller already has a 40A maximum phase current programmed in that works well, while the Phaserunner or Baserunner allow you to customize this setting exactly. Up to 40 amps can be used on the standard winding, 48 amps on the fast winding, and 55 amps for the very fast winding.

Loose Magnets from Fast RPM

Another limitation on these hubs is (being an inunner) they rely on magnet adhesives to hold the magnets on the rotor. If the motor ends up spinning too fast, especially when it is hot and the adhesive strength is reduced, then the centrifugal forces can cause the magnet to lift off the rotor and scrape against the stator. This results is a sudden loud raspy sound from the engine which goes away once the motor speed is reduced. If the motor is allowed to run for a length of time with the magnet scraping like this, it will overheat and demagnetize the loose magnet. Otherwise if it's caught early enough then the magnet can be glued back to the stator to no ill effect.

Another limitation on these hubs is (being an inunner) they rely on magnet adhesives to hold the magnets on the rotor. If the motor ends up spinning too fast, especially when it is hot and the adhesive strength is reduced, then the centrifugal forces can cause the magnet to lift off the rotor and scrape against the stator. This results is a sudden loud raspy sound from the engine which goes away once the motor speed is reduced. If the motor is allowed to run for a length of time with the magnet scraping like this, it will overheat and demagnetize the loose magnet. Otherwise if it's caught early enough then the magnet can be glued back to the stator to no ill effect.

On our first samples of G310 motors we were able to run the hubs at 450 rpm continuously without any issues. However, on our first large sea shipment in 2018 we were experiencing cases of magnets coming loose as low as 300 rpm, or 40 kph in a typical ebike. On that run we ended up opening and regluing the magnets ourselves using a high temperature rated thermally cured epoxy adhesive which was a lot of work. Bafang has improved this situation with our current 2019 shipment but it's still not as good as the magnets that we glue ourselves. The stock motors can be used up to 350 rpm, equivalent to the standard wind motor at 48V or a fast wind at 36V. If the motor will be used in a faster application (with 52V batteries or with fast windings in smaller wheel sizes) then we offer a reglued magnet option that will work up to 500 rpm. 2021 Update: All of our 8T fast wind G310/G311 motors come stock with a special magnet adhesive that is immune to this problem.

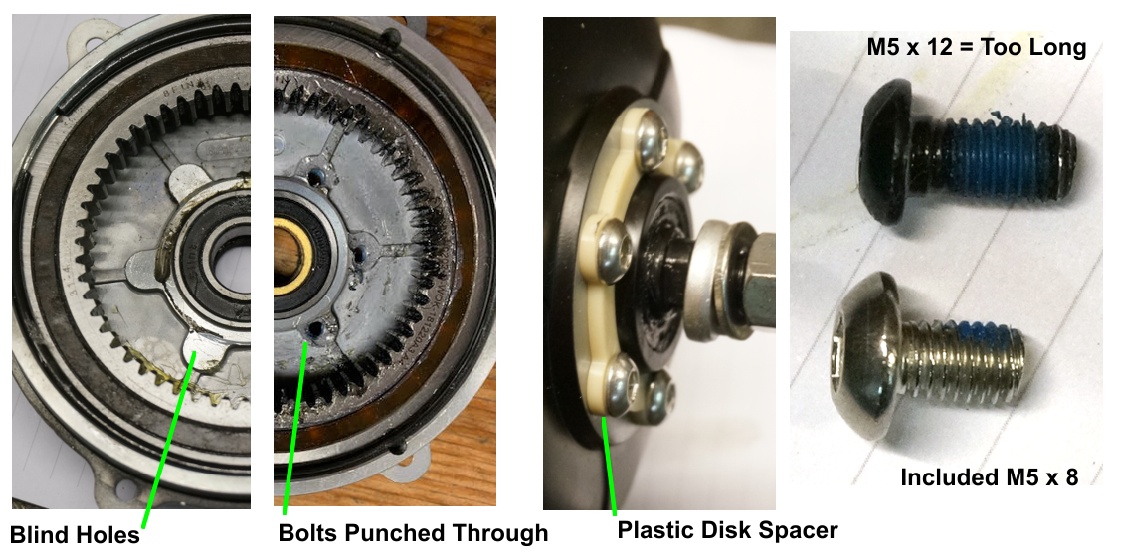

Maximum Disk Bolt Length

The G31X motors use blind holes for the disk screws which is great since it means that there is no opportunity for water ingress. However, that also means that if longer screws are used there is a risk of them punching right through the side cover casing and injecting broken bits of metal casting inside the hub, which will inevitably wreck the nylon gears. This can also happen with the original screws if the plastic disk spacer is removed from the hub and then the screws put back in all the way. The disk bolts for the G31X motors should not be longer than M5 x 10mm and the stock screws that come with the motor are M5x8mm. Many disk rotors are supplied with 12mm bolts included, and you should not use them unless you put washers under the head to limit the thread depth to the hub.

The G31X motors use blind holes for the disk screws which is great since it means that there is no opportunity for water ingress. However, that also means that if longer screws are used there is a risk of them punching right through the side cover casing and injecting broken bits of metal casting inside the hub, which will inevitably wreck the nylon gears. This can also happen with the original screws if the plastic disk spacer is removed from the hub and then the screws put back in all the way. The disk bolts for the G31X motors should not be longer than M5 x 10mm and the stock screws that come with the motor are M5x8mm. Many disk rotors are supplied with 12mm bolts included, and you should not use them unless you put washers under the head to limit the thread depth to the hub.

CAD Drawings

G310 Rear Motor Dimensional Diagram from Grin

G311 Front Motor Dimensional Diagram from Grin

Videos

Where to Order

Canadian

Canadian

Grin Online Store, G31X Kits

Grin Online Store, G31X Kits